SURA Instruments GmbH is one of the leading worldwide manufacturers of preliminary machining and surface treatment systems and resources. Thanks to their high qualifications and great experience in surface technologies, the company’s solutions are specific to the application and advantage oriented, and they lead to an increase in adhesion of ink, lacquer and glue for clients in the automotive, packaging, steel, glass and medical industries. Their basic technology is the PYROSIL® process, also known as flame silicification. Tampotechnika sp. z o.o. is the representative of SURA Instruments GmbH in Poland.

PYROSIL® began as a dental adhesion system developed in cooperation between scientists at the Friedrich-Schiller-Universität Jena and Heraeus Kulzer GmbH & Co. KG under the special direction of Prof. Dr. Tiller and Prof. Dr. Musil, starting in 1985. Since 1997, the scope of the PYROSIL® technology has continually broadened to include solutions outside of the medical industry.

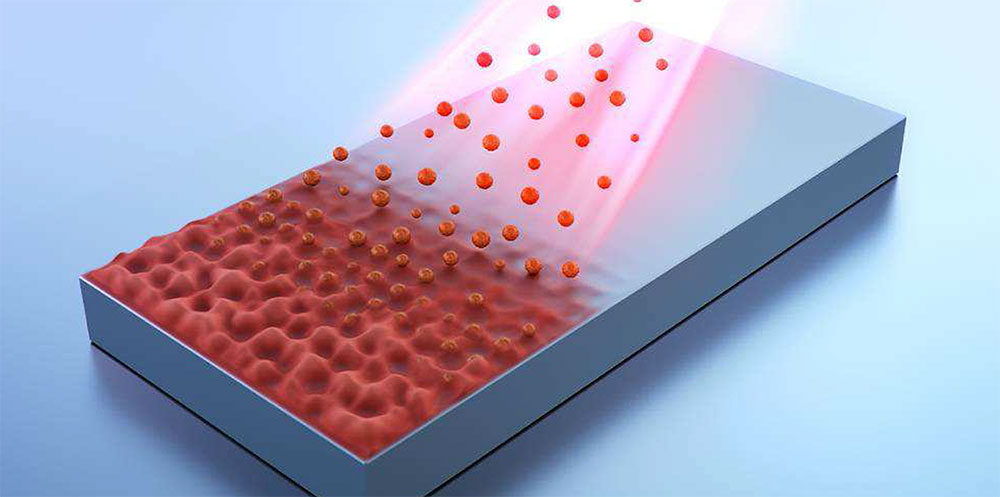

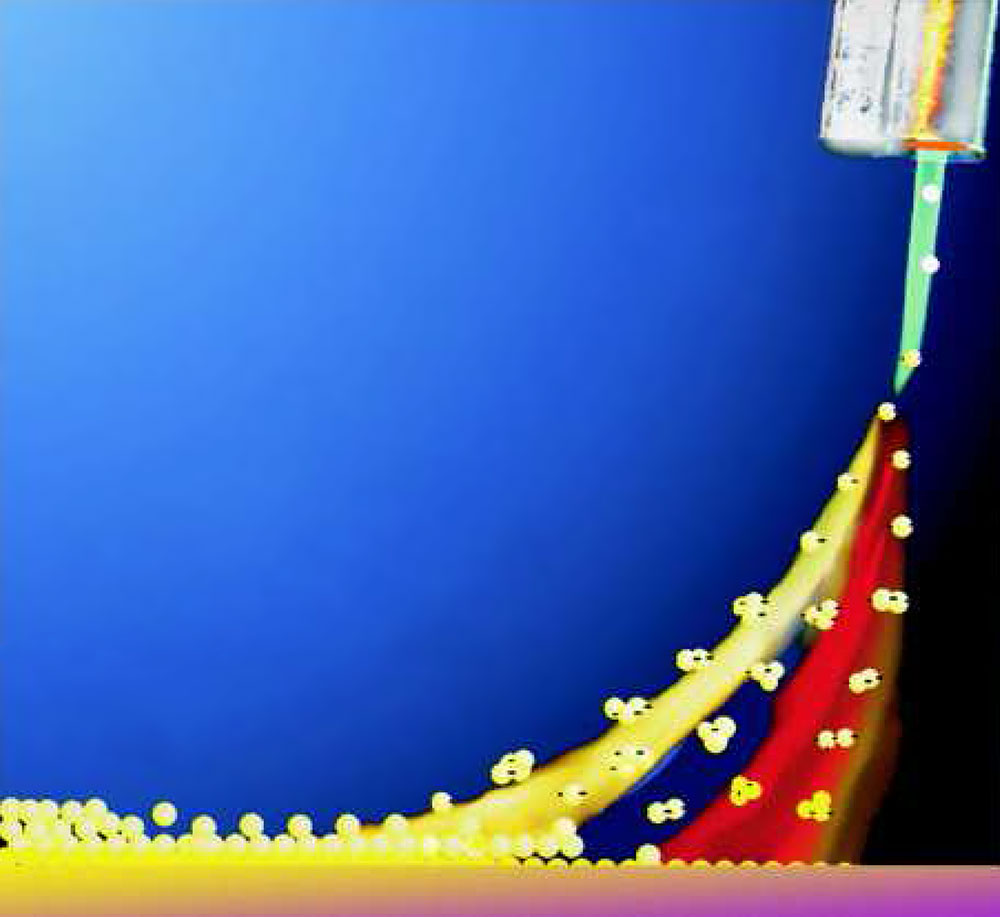

The PYROSIL® process is based on the deposition of silicon compounds SiOx(OH)(4-2x) on the product surface. The surface is fed through a gas flame doped with a silicon containing substance, called a precursor. The presence of the precursor causes the flame to become more red. The precursor burns in the flame, in a process similar to pyrolysis (the burning of chemical compounds in high temperatures), and deposits on the surface in a very thin (5 – 100 nm) but dense and firmly adhering silicon oxide coating. Due to the short flame-substrate interaction the material’s surface temperature remains moderate. Thus, the PYROSIL® Process is suitable not only for glass, ceramics or metals, but also outstanding for plastics. The increase in polar Si-OH bonds allows for the application of a wide range of organic coatings (ink, lacquer, glue) and further chemical modifications of the substrate, for example the use of a primer.

Coating properties:

- Roughening (nano-porous) of the material surface

- Hydrophilisation of the surface, very high surface energy

- Invisible and flexible coating

- Long-term stable coating (in combination with a primer, it can be stored without activation loss for 1 – 4 weeks before further processing

Process properties:

- Effective and cost-efficient scalable process

- Low temperature protects material

- Can be used for nearly any materials

- Parameters can be customised for customer requirements

- No toxic compounds are created during usage

Zastosowania:

- Adhesion promotion (gluing, varnishing)

- Corrosion protection (galvanized steel)

- Wettability promotion (glass)

- Creation of well defined chemically reactive spots on the surface

- Sealing layers

- Barrier coatings against alkaline ions and gases

- Adjustment of optical properties