The most widely used method of preparing plastic items for direct printing, gluing, or varnishing is oxidation using a gas flame.

At the high temperature of the gas flame, oxygen particles break down into free oxygen atoms, and the exhaust gases contain active carbon and nitrogen molecules, free electrons, and positively charged ions. The resulting gas plasma has a lower density and electron energy compared to corona discharge, but its mass flow is significantly higher.

The effect of the flame is determined by four parameters, the correct selection of which will ensure the best activation result:

· Mixture composition – the ratio of air to gas

In order for the gas flame to have oxidizing properties, combustion should take place with an excess of air (“lean” mixture). The excess air should be 3-5%.

· Thermal power of the burner

The thermal power of the burner is closely related to its design and mixture composition – too low burner power may result in the object having to be moved too slowly, which may cause it to overheat.

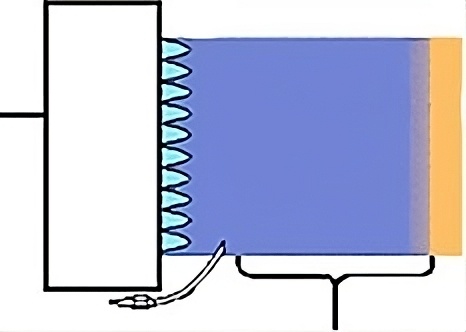

· Distance between the prepared surface and the active part of the burner

The zone of strongest impact is between 10 and 12 mm from the light blue tips of the flame. Increasing this distance means entering a zone of weaker impact. Contact between the prepared surface and the light blue tips of the flame will reduce the effect.

Range of effective impact

· Exposure time

The exposure time should be as short as possible. Too long exposure time may damage the surface of the object. A shiny surface may become dull, and a matte surface may become shiny.